New means of production

Today the company Creat produces various parts of elastomers (NBR, FKM, EPDM, CR and FFKM) from simple O-ring to the room plan by offering various approvals (Aeronautics, rail, food ...).

All parts are 100% produced in France, from tooling through the raw materials to the design of parts in other words molding. Créat has adapted to market demand and incorporates full part traceability at all stages of production.

Creat is equipped with the latest generation of compression and injection molding. This new press has a production capacity of 160 tons and allows realizing larger parts in medium and large series while memorizing and plotting production conditions (curing time, temperature, pressure ...).

To meet industry’s requirements, Créat invested in a digital proofer which allows knowing the temperature data, to post baking statements, but also to communicate the full traceability of parts to the customers.

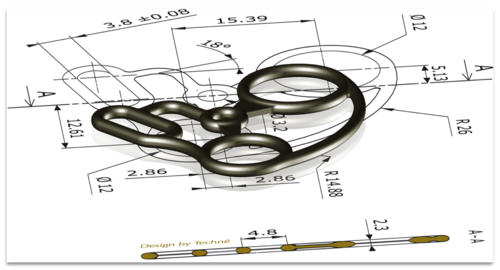

The elastomers are flexible and deformable; Creat utilizes a programmable optical three-dimensional machine for control of the production. It provides an accuracy of 1 to 2.5 microns according to the measured length. The program allows repeat measurements via a fixed and automatic protocol.

Creat will be present at the Air Show Salon du Bourget from June 19 to 25, 2017 in Paris to present all its innovations.

Efficient human resources

Creat is now equipped yourself with technical and human resources to bring its experience to its customers.

To continue its development, Creat also strengthened its human resources by recruiting qualified and specialized sealing and molding personnel.